Face Masks Are Piling Up In Warehouses, Indy Makers Say

AUSTIN, Texas – It was a dire situation that Lloyd Armbrust can almost laugh about now.

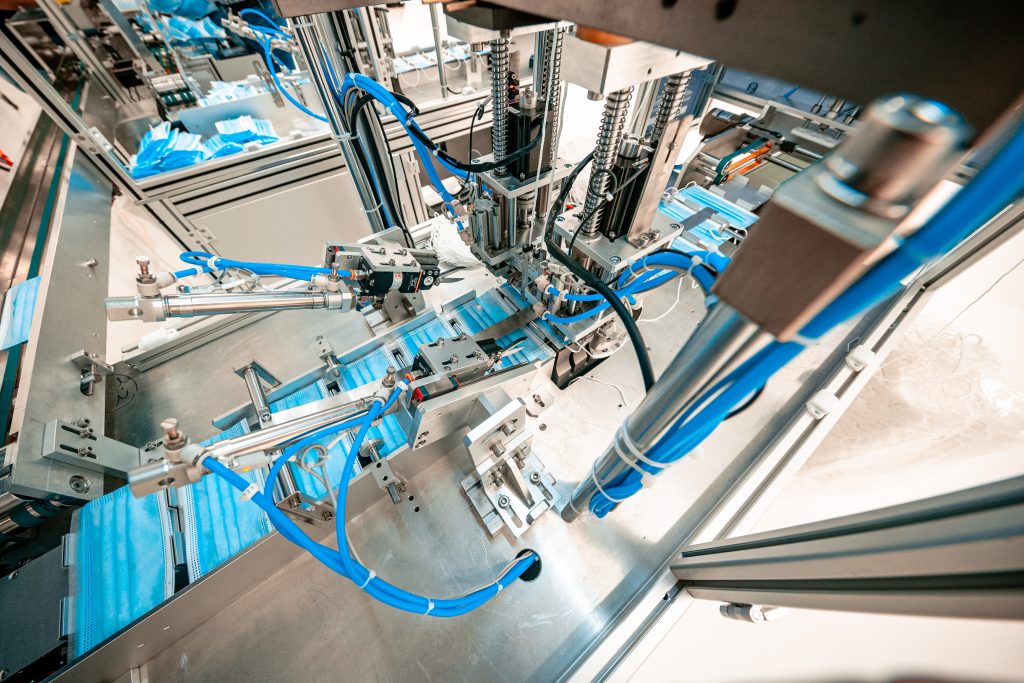

A global pandemic had swept across the United States, a baby was on the way, and Armbrust, hard as he tried, could not find a supply of a critical element of the N95 face mask he’d just formed a company to make.

It was April 2020 and the pandemic had disrupted critical supply chains. Everyone was scrambling.

And everywhere that Armbrust looked, not a smidgen of “meltblown,” the non-woven fabric material that is crucial to filtering out microscopic particulate matter, could be found.

“We had ordered our first mask manufacturing machine from China, and it was being flown in, and four of the five parts of the masks we wanted to make were pretty easy to source,” Armbrust said.

“But ‘meltblown’, the most important and most expensive part of each mask, proved to be almost impossible to find,” he said. “Finally, after spending days and days at this, I turned to Landon Morales, my president and head of sales and said, ‘I’ve got to delegate this thing to you. And this is a must-win situation for our company, because if we don’t get this, we can’t make the masks.’”

“Literally, all of the investment we’d made to establish the company would have been for nothing,” Armbrust added.

Morales, a cool head who’d had success scaling companies across a variety of industries, didn’t flinch. He drew up a list of about 300 people in the United States whose LinkedIn profile suggested they had anything to do with the face mask business.

Then he called each one, asking if they had any meltblown to spare.

“He literally got to the last name on the list, and as it happened, the guy had been in a related business for years and had just gotten a big order of it,” Armbrust said. “So we basically begged them to sell us 2000 pounds of the stuff, and they charged us $100,000 – or about $50 a pound.

“Now, today, I can get the same material for about $8 a pound, which shows you how insane everything had gotten around the pandemic,” he said.

But that wasn’t the end of it, Armbrust said. If he wanted the critical component of his product, he was told, he’d need to send someone from his company’s home base in Austin, Texas, to Detroit to get it.

“And it was literally a situation where we had to meet them in a parking lot in Detroit. My guys were there. I was on the phone with the seller. And I had to wire them the money before the meltblown could be moved from one truck to another. It was like some kind of drug deal, but again, that’s how crazy things were in the PPE business back then.”

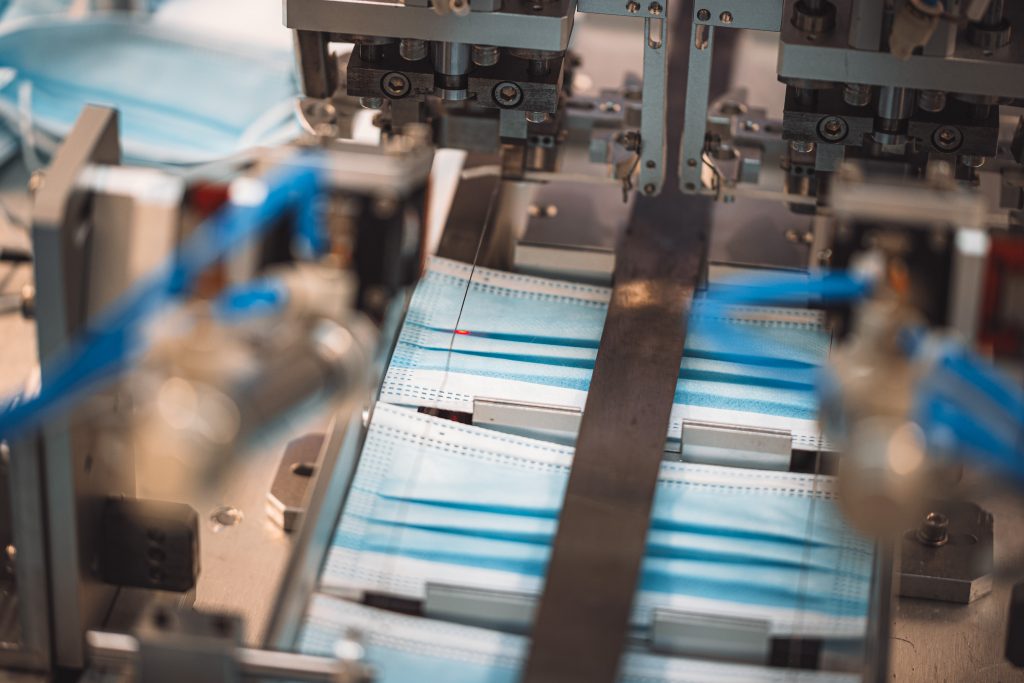

Armbrust’s company, Armbrust Inc., manufactured its first face mask on May 5, and for the next three months, every mask that came off the assembly line was being boxed and sent to a waiting hospital, first responder, volunteer or consumer.

One particularly big contract last summer was with the state of Texas, which bought 10 million masks from the company to provide to its teachers.

But something fundamental happened in the face mask marketplace. Sometime between late summer and mid-November, “a switch flipped,” in Armbrust’s words. Despite continued demand, he suddenly found himself with excess stock on hand.

“Right now,” he told The Well News earlier this week, “I probably have 30 million plus masks in my warehouse and I know a number of other small manufacturers who can tell you the same.”

In fact, a group of independent, U.S.-based manufacturers called the American Mask Manufacturers Association says its members currently have an inventory of about 233 million N95 respirators or equivalent masks in their warehouses and the capacity to manufacture 298 million per month.

And this at a time when high-quality respirators — masks capable of filtering out many of the tiny aerosols that carry the coronavirus — remain out of reach for millions of Americans.

That’s why he and his fellow independent face mask manufacturers were heartened to learn on Jan. 21 that President Joe Biden, in one of the many executive orders he signed that day, directed the Occupational Safety and Health Administration to draft a guidance that would essentially mandate that every business have a certain level of face masks and other PPE on hand for their employees.

Anecdotally, the manufacturers subsequently heard that OSHA was for such a move, but they also heard that the Centers for Disease Control was telling the agency that such an order was impossible, and that there is still no adequate supply of N95 masks in the United States.

“I know that’s not true, because I’m looking at my warehouse filling up,” Armbrust said.

“Yes, there was a major supply problem early on in the pandemic, one issue being logistics, but now I think what we’re seeing is more of a communication problem,” he said.

The American Mask Manufacturers Association started out as an ad hoc working group of independent manufacturers who were trying to help each other over various mundane hurdles as they sought to help address a national emergency.

But after they saw much larger entities, like Kimberly Clarke and 3M net big contracts from the Trump administration, they decided the time had come to pool their resources and get their message out.

“I mean it’s just basic common sense. If the government doesn’t know that we exist, they won’t know we’re here to meet the supply needs of the moment,” Armbrust said.

Earlier this week, the group wrote a letter to President Biden, COVID-19 Response Coordinator Jeff Zients, National Institutes of Health senior official Anthony Fauci and CDC Director Rochelle Walensky, urging them to recognize America’s independently-run manufacturers are able to produce enough high-filtration masks today to protect every American in need.

Specifically, they said, as of today, they have a combined 690 million high-filtration masks sitting in American warehouses ready to ship, containing:

- 456.9 million surgical masks (proven effective by the CDC when combined with a mask brace or cloth mask);

- 233.4 million N95 respirators (or equivalents); and

- 50,000 reusable elastomeric respirators.

In addition, they say they have a current monthly production capacity of 902.3 million made-in-America masks, consisting of:

- 603.5 million surgical masks;

- 298 million N95 respirators (or equivalents); and

- 671,000 reusable elastomeric respirators.

If given a $75 million government investment, they estimate they could ramp up monthly production to supply enough surgical masks and respirators for every American each month.

But what they say they need first, is for the CDC to issue a new guidance on face masks that recognizes the supply and capacity out there to manufacture as many masks as needed right here in the United States.

And time is of the essence, as OSHA is supposed to take some kind of action of President Biden’s order by March 15.

“I haven’t spoken to anyone at the CDC, but their position, as outlined on their website is that we are in a crisis and that N95s should be reserved for health care workers because relaxing the guidance could lead to a run on supply,” Armbrust. “We’re arguing that fear is no longer justified.”

The CDC did not respond to a request for comment.

Despite the very clear issues at hand, Armbrust said “I will give it to the Biden administration, they’re trying their best.”

In their letter the manufacturers urge the administration to take additional steps, including ending the practice of rationing critical PPE supplies and provide them with funding needed to protect health care workers; direct the Departments of Health and Human Services and Defense to issue Title III funding to mitigate risk for independent manufactures to increase production; to provide guidance on strategic distribution of these American-made masks; and to explore formal partnerships with American domestic manufacturers as part of continuing efforts to respond to COVID-19 and future emergencies.

And what if that doesn’t happen?

Tom Cheredar, a spokesman for Armbrust Inc., who was sitting in on the conversation said without these steps being taken, along with others, many of the association’s member companies will simply go out of business.

As things stand now, these independent companies are not allowed to sell their products overseas due to FEMA and the CDC, and they’re also locked out of selling their wares to most hospitals.

“If we don’t see some sort of movement … a change from the CDC, a change in the way hospitals buy things, a change in how the government chooses to replenish its stockpile of these goods, I would say at least 50 of our 62 manufacturers are going to go away,” Cheredar said.

If anything, Armbrust was even more sobering.

“In my opinion, people will die unnecessarily. I mean, we know that COVID is airborne, that it travels more than six feet, and that it can stay in the air for hours. So if you have people in an enclosed space – particularly one that’s not properly ventilated, people who are not wearing masks are going to get sick. And some are going to die. How many? I don’t know. Is one life, okay? Is 100?‘Is another 500,000? I don’t know. I’m not one that can make that decision. But I think it’s something we should prevent if we can.”